|

Technica Integrated Engineering Co. Ltd. Unit 1211, New Tech Plaza, 34 Tai Yau Street, San Po Kong, Kowloon, Hong Kong.

Tel: (852) 2804 2209 Fax: (852) 2529 7226 email: info@technica.com.hk

|

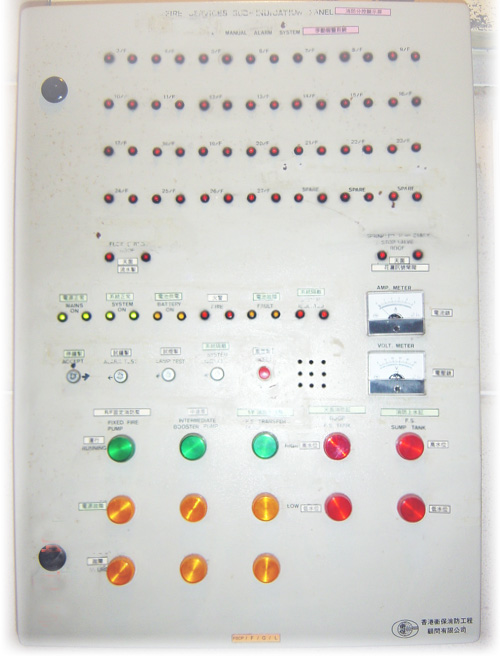

Central control and monitoring systems (CCMS) are of various levels of sophistication depending on the size of the building and desired operational function. The simplest system allows an operator to check the operational status of the heating, ventilating and air conditioning (HVAC), fire and security systems, and control various equipment remotely from a central console. The most complex system (electronic devices) has a digital computer to perform most of the work normally and other optimization and control functions, done by the operator.

Total cost and the number of points monitored are used to develop a simple

guideline for selecting a suitable system for a given large building or

group of buildings. For a particular building or building complex, the

preliminary survey of the existing building equipment system and desired

control functions will indicate the total number of points to be

monitored. The results are used to estimate the initial cost and determine

which system is most suitable.

An intelligent building automation system enables maintenance personnel to

better manage resources, improve building safety, and reduce energy costs.

With electronic device networking technology, an intelligent building can

be created, allowing maintenance team to control virtually every system

anytime and anywhere. A modern CCMS make it possible to integrate building

sub-systems (including security, HVAC, lighting, elevators and safety

systems) into a single, efficient building management network. For an

example, the estates manager at a depot station can control everything

from a simple alarm to a sequence of systems activation, and can even

diagnose system problems remotely with a mobile phone. Start/Stop Program -- This represents the simplest yet most effective, energy saving program. It is designed to start and stop different HVAC equipment automatically according to a pre-determined schedule. Reset Program -- The actual cooling load is calculated in various zones and the supply air temperature reset so that minimum cooling and reheating will occur. This action saves energy by matching the system to the actual building load during off-design conditions. Start Time Optimization Program -- Comfort conditions are restored in time for occupancy in buildings where the air-conditioning equipment is shut down during the silent hours. Electric Demand Control Program -- The controllable or discretionary portions of the building electric load are varied to compensate for load requirements elsewhere in order to present a more nearly constant total building demand to the utility company. Enthalpy Control Program -- This program is also known as the outdoor air quantity optimization program. When a space requires cooling, the enthalpy (total heat content) of the outdoor and return air are monitored and compared. Thus, when the enthalpy of the outdoor air is lower than that of the return air, a larger percentage of outdoor air is mixed with a smaller portion of return air. This in turn reduces the chillers load, and is therefore called "free cooling." Chiller Load Optimization Program -- This program is used when a group of buildings is supplied with cold water for the cooling system by a multiple chiller plant. It is designed to maximize the cooling plant efficiency during all operating conditions and ensure minimum energy consumption. The over-all cooling plant efficiency varies with the imposed cooling load, condenser water temperature, and chilled water temperature. Interactive calculations determine the most efficient operating conditions by taking into account cooling plant layout, the number of series and parallel chillers, and whether or not a heat recovery system is used. Building Management Programs -- Standard programs are used to provide integrated daily or monthly cooling and heating loads, kilowatt- hours, kilowatt demand, and total gas, oil and electricity consumption. Preventive Maintenance Program -- Totalization of machine running time enables maintenance personnel to service different equipment properly, based on total accumulated running time. Light Control Program -- This program is used to control lights in various zones of a building or group of buildings. A direct and profitable advantage of a light control system is the ability to reduce electric peak demand quickly when it reaches the critical range. Fire Alarm and Life Safety Program -- A databased computerized system for life safety, fire alarm, and smoke control operations can be designed to work in parallel with HVAC systems. Smoke control routines include control of special fans and air-handling units. Power Demands Forecast Program -- When the predicted electric power demand appears to exceed a preselected usage limit, the central facility is alerted and the electric demand control program is executed.

Building automation systems are vital to maintaining

environmental comfort, security and safety, while minimizing energy costs

and operating expenses. We provide a total-solutions approach to building

automation with a comprehensive range of controls for your business,

institutional or commercial needs. Solutions are custom-tailored based on

your facilities' size, hours of operation, type of use, desired climate,

and operating budget goals.

|